CPM valves maintain uniform inlet or outlet pressure in hygienic process lines for the dairy, food and beverage industries. These regulating valves provide accurate pressure control, safe and reliable performance and excellent cleanability.

- Safe, effective pressure control

- Excellent valve cleanability

- Constant pressure valve range

- Compliance with most hygienic standards

- Aseptic version

- Product Benefits

- Food logic

- Каталог продукции

- Принцип работы

- Construction

- Operating principle

- Options

- Alfa Laval — Unique RV-P

- Extremely accurate valve flow regulation

- Advanced hygienic valve design

- Extreme valve accuracy

- Regulating valves with Unique SSV modularity

- Aseptic version

- Low maintenance requirements

- Compliance with most hygienic standards

- Alfa Laval — Unique RV-ST

- Hygienic corrosion-free regulating valve

- Advanced electro-pneumatic controller

- Easy push-and-play regulating valve setup

- Reliable, easy to maintain

- A regulating valve with maximum flexibility

- Alfa Laval — Регулирующий клапан Unique LKB

- Intelligent reliability and control for butterfly valves

- Simplified setup for butterfly valve control

- One size actuator fits all LKB butterfly valves

- Easy upgrade for butterfly valve actuators

- Valve control and automation range

- 🎥 Видео

Safe, effective pressure control

Alfa Laval Constant Pressure Modulating (CPM) valves are pneumatic regulating valves that maintain a constant inlet or outlet pressure in hygienic process lines. Thanks to a quick response diaphragm, these compact valves immediately react to any change in product pressure, adjusting position to keep the pressure at preset values.

Excellent valve cleanability

CPM valves feature a self-draining design and crevice-free, bowl-shaped valve body with welded valve seat to enable thorough cleaning, thus eliminating potential entrapment areas. The unique diaphragm with PTFE on the lower diaphragm also contributes to excellent cleanability.

Constant pressure valve range

Alfa Laval offers three types of CPM valves. Modular design enables the use of different plug sizes and different flow rates between 0.5 and 110 m3/h provide great operational flexibility.

Upon request, some CPM valves can be provided as ATEX-approved valves (group 2 category 3 D&G applications) for use in potentially explosive areas.

For more information, please refer to How it works and Documentation.

Compliance with most hygienic standards

Alfa Laval CPM valves meet most standards requested in the dairy, food and beverage, and personal care industries. Please refer to Documentation for more information.

Aseptic version

Designed to maintain a constant pressure at the valve inlet or outlet, using different plug sizes and different Kv values.

The diaphragm in the valve enables it under aseptic conditions to react effectively to any changes in product pressure by shifting position against a constant air pressure.

The CPM valve is often used upstream of aseptic filling and bottling machines.

Product Benefits

The essentials for future foods

Alfa Laval’s hygienic equipment combines high performance with gentle handling to preserve sensitive ingredients.

Food logic

Каталог продукции

Онлайн-версия каталога «Close at hand»

Видео:Обзор клапана Alfa Laval CPMIСкачать

Принцип работы

Construction

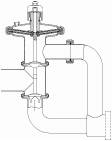

There are two different types of construction for Alfa Laval Constant Pressure Modulating valves.

The CPMI-2 and CPMO-2 valves consist of a valve body with valve seat, cover, a valve plug with a special diaphragm and a clamp. The diaphragm consists of two flexible EPDM diaphragms supported by 12 stainless steel sectors in between them. The cover and the valve body are clamped together. The valve body and the seat are welded together.

The CPM-I-D60 consists of a CPMI-2 valve with additional piping.

Operating principle

The CPMI-2, CPMO-2 and CPM-I-D60 valves are controlled remotely by means of compressed air. The valves operate without a transmitter in the product line and only require a pressure-regulating valve for the compressed air and a pressure gauge in the product line (see below).

Читайте также: Лепестковые клапана для тайги

Where modulating back pressure is required (i.e., to maintain a fixed flow in and out of the CPM valve), the air supply to the valve can be provided by an I/P converter (typically 3-15 psi) and a booster valve. The product pressure dictates the pressure ratio of the booster valve.

A diaphragm reacts immediately to any alteration of the product pressure and changes position so that the preset pressure is maintained.

Inlet side: The Constant Pressure Modulating Inlet (CPMI-2) valves and the Constant Pressure Modulating Inlet D60 (CPM-I-D60) valves maintain constant pressure in the process line at the inlet side of the valve. CPMI-2 and CPM-I-D60 open when product pressure increases and close when product pressure decreases. These are often installed downstream from separators and heat exchangers, and may also be used as overflow valves.

Outlet side: The Constant Pressure Modulating Outlet (CPMO-2) valves maintain constant pressure in the process line at the outlet side of the valve. CPMO-2 closes when product pressure increases and opens when product pressure decreases (see illustration below). It is often installed upstream from pasteurizers, separators and filler systems of filtration units.

Options

- Fittings in accordance with required standard

- Air pressure regulating valve kit, 0-8 bar

- Diaphragm in PTFE covered in EPDM or PTFE

- Seals in NBR, FPM or PTFE

- Air throttling valve for adjustment of regulating speed for the CPM-2 valve

- Booster for product pressure exceeding the available air pressure (Product pressure = 1.8 x air pressure)

- 3A version available on request for CPMI-2 and CPMO-2 valves only

Constant-Pressure Modulating Inlet Valve

Constant-Pressure Modulating Outlet Valve

Constant-Pressure Modulating Inlet Valve D60

Видео:односедельный клапан Alfa Laval Single Seat Valve SSVСкачать

Alfa Laval — Unique RV-P

The Unique RV-P regulating valve is designed to safely and effectively control or regulate precision flows in the dairy, food and beverage, and biopharm industries.

Extremely accurate valve flow regulation

Alfa Laval offers two regulating valves:Unique RV-P and an aseptic version, Unique RV-P Aseptic. These normally open or normally closed regulating valves provide highly accurate control of pressure, flow, temperature and fluid levels in tanks and in steel pipe systems.

Advanced hygienic valve design

Unique RV-P valves are ideal for high-volume sanitary process applications that require precision control. With a self-draining valve body, these valves are authorized to carry the 3-A symbol. Especially suitable for aseptic applications that require SIP (Sterilization in Place), the Unique RV-P valves are fitted with PTFE diaphragms that prevent contamination from microorganisms and particles outside the product zone.

Extreme valve accuracy

The Unique RV-P features an electro-pneumatic actuator with integrated IP converter and integrated positioner, which contribute to greater operational accuracy and reliability. The positioner for Unique RV-P valves are IP66 certified for water and dust protection.

Regulating valves with Unique SSV modularity

The pneumatic actuated regulation valves from Alfa Laval are both built on the same Unique SSV platform and thus modular with the Alfa Laval single seat valve range. The Unique RV-ST is ideal for standard regulating duties like metering, blending, weighing and filling.

If the regulating demands increases then the Unique RV-P is the optimal choise. With a high precision actuator and positioner it is ideal for regulation in applications where the highest accuracy is required. Based on modular components different plug configurations can be selected to meet specific Kv requirements. The lower sealing element is clamped on and can be replaced to match flexible Kv values.

Читайте также: Решетка приточная регулируемая с клапаном рэд р1 крв

For more information, please refer to Documentation.

Aseptic version

The aseptic version of Alfa Laval’s Unique RV-P is called Unique RV-P Aseptic. This is an electro-pneumatic modulating valve that features an IP converter as an integrated part of the actuator. Available with a range of plug designs with different Kv values, providing different capacities.

Supplied with a an aseptic diaphragm that provides hermetic sealing against intrusion from the atmosphere, ensuring full protection against the effects of micro-organisms during processing. This design allow aseptic control of pressure, flow, temperature in aseptic systems and to control the level of liquids in aseptic tanks.

Like all Alfa Laval valves, the Unique RV-P Aseptic is constructed with few moving parts housed in the actuator for added wear protection. Its compact hygienic design contributes reduces the need for maintenance and makes disassembly, if required, quick and easy. Plus there are no loose springs to pose any safety risk when opening the valve. The diaphragm is fully modular with the well proven diaphragms from the Unique SSV Aseptic portfolio.

Low maintenance requirements

Like all Alfa Laval valves, the Unique RV-P is constructed with few moving parts housed in the actuator for added wear protection. Being modular with the Unique SSV portfolio it is possible to optimize maintenance routines and spare parts inventories in the plant. Its compact hygienic design contributes reduces the need for maintenance and makes disassembly, if required, quick and easy. Plus there are no loose springs to pose any safety risk when opening the valve.

Compliance with most hygienic standards

Alfa Laval Unique RV-P valves meet most standards requested in the dairy, food and beverage, and personal care industries. Please refer to Documentation for more information.

Видео:Alfa laval 309 проверка водяного режимного клапана управления барабаномСкачать

Alfa Laval — Unique RV-ST

With an integrated IP converter and push-and-play setup, the Unique RV-ST regulating valve meets the highest process demands for hygiene and safety. Built on the Unique SSV platform, it is ideal for high-volume sanitary liquid processing applications.

Hygienic corrosion-free regulating valve

The Alfa Laval Unique RV-ST is an intelligent hygienic regulating valve that safely and effectively controls process flows with Kv values between 9 and 246 m 3 /hour. It is designed for a wide range of fluid handling duties, such as metering, blending, weighing and filling system duties, in the food and beverage, brewery, biotech and pharmaceutical and chemicals industries. Corrosion-free features, such as tapered stainless steel stems, ensure product safety according to EHEDG (European Hygienic Engineering & Design Group) guidelines.

Advanced electro-pneumatic controller

The Unique RV-ST regulating valve comes with an advanced electro-pneumatic controller with an integrated IP converter. This offers superior control of product flow by combining different pressure drops and stroke lengths. It also features a contact-free analog position sensor, which measures the position of the valve spindle, and a standard Profibus DP-V1 or optional DeviceNet communications interface. Analogue or binary feedback is available as options.

Easy push-and-play regulating valve setup

With a push of a button, the Alfa Laval Unique RV-ST regulating valve automatically calibrates itself so that it is fully operational.

Reliable, easy to maintain

Built on the proven Unique SSV (Single Seat Valve) platform, which has an installed base of more than one million valves, the Alfa Laval Unique RV-ST UltraPure offers the same reliability, safety and ease of maintenance. Its offers protection class IP65 and IP67 for tough process environments.

Читайте также: Сколько нужно лить масла в двигатель приора 16 клапанов

A regulating valve with maximum flexibility

It uses the same few moveable components, spare parts and maintenance tools and procedures as Alfa Laval Unique SSV valves. Using the upgrade kit available, it is possible to upgrade older regulating valves with the new control unit. The new control unit also supports rebuild of the actuator from NC (Normally Closed) to NO (Normally Open) and vice versa.

Видео:Сепарационная система Альфа Лаваль CulturefugeСкачать

Alfa Laval — Регулирующий клапан Unique LKB

The Unique Control LKB automation unit with built-in actuator offers intelligent control for LKB butterfly valves used in all applications. This straightforward all-in-one actuator offers superior flow control, hygiene, durability and reliability.

Intelligent reliability and control for butterfly valves

The Alfa Laval Unique Control LKB is an integrated valve control unit and actuator with an enhanced hygienic one-piece design. Tested to over a million strokes without service, Unique Control LKB is the most durable actuator available today. Its well-built design withtough composite casing withstands most harsh environments.

IP66/IP67-approved, the Unique Control LKB features superior technology, shape and material, which prevent condensation and the penetration of dust, water and other particles into the unit. This contributes to maximum hygiene and effectively eliminates problems associated with corrosion, external contamination and the effects of physical impact, including vibration, pressure shock, frost, heat, UV radiation and environments polluted with grease, oil and chemicals, without disrupting production.

In addition, the Unique Control LKB provides integrated automation with a clear 360° visible indication and an air surveillance system for reliable real-time monitoring of the operating air pressure. Instead of being controlled by a conventional mechanical spring like most butterfly valve actuators, an air spring controls the actuator of the Unique Control LKB. This, combined with the intelligent capabilities of the sensing and control unit, enables operation at a lower air pressure and delivers significant benefits in terms of durability, reliability and more system uptime.

Simplified setup for butterfly valve control

Push n’ Play self-configuration gets the Unique Control LKB up and running five times faster than conventional solutions. Simply press one button and the Unique Control, which is compatible with both digital and AS interfaces, configures and calibrates itself to ensure the best possible mode of operation. This convenient one-button process saves time and money.

One size actuator fits all LKB butterfly valves

For ultimate convenience, a single actuator is suitable for most valve solutions thanks to the high torque, which enables the unit to fit any valve size. In addition, it is easy to switch from normally open (NO) to normally closed (NC) and vice versa onsite. This one-size-fits-every-valve design makes engineering, ordering, installation, onsite configuration and stock keeping easy.

Easy upgrade for butterfly valve actuators

The Unique Control fits all manual and actuated butterfly valves in the Alfa Laval LKB range. Existing installations are easy to upgrade to Unique Control LKB; all that is required is a new bracket. Simply order the optional bracket kit for that particular LKB valve size in order to mount the Unique Control unit easily onto any of the 1” to 4” and DN25 — DN100 valves in the LKB valve range.

Valve control and automation range

The Unique Control LKB offers intelligent automation and control of Alfa Laval LKB butterfly valves and complements our broad range of valve control and automation solutions.

🎥 Видео

Запорный клапан DN 50 для охладителя молока Alfa Laval, DelavalСкачать

Doubleseat valve (mixproof) / Двухседельный клапан (противосмесительный)Скачать

Декантер Alfa Laval. Демонтаж редуктора декантера. Как правильно демонтировать редуктор декантера?Скачать

CPMOF Valve - MaintenanceСкачать

Декантер Alfa Laval. Монтаж и установка редуктора декантера. Как установить редуктор декантера?Скачать

НПО Регулятор. Клапаны регулирующие седельного типаСкачать

Типы регулирующих клапановСкачать

BardianiValvole B925 двухседельный клапан - матрицаСкачать

Alfa Laval Unique single seat valves - maintainable actuatorСкачать

Alfa Laval Unique SSV (Single Seat Valve) Maintenance Instruction VideoСкачать

Mantenimiento de la válvula Alfa Laval Mixproof CP-3Скачать

Separator Alfa LavalСкачать

Alfa Laval Unique mixproof valves - replace product-wetted sealsСкачать

Сливной клапан ELVA нормальной закрытый DN50 220В для охладителей молока Alfa Laval, DeLavalСкачать